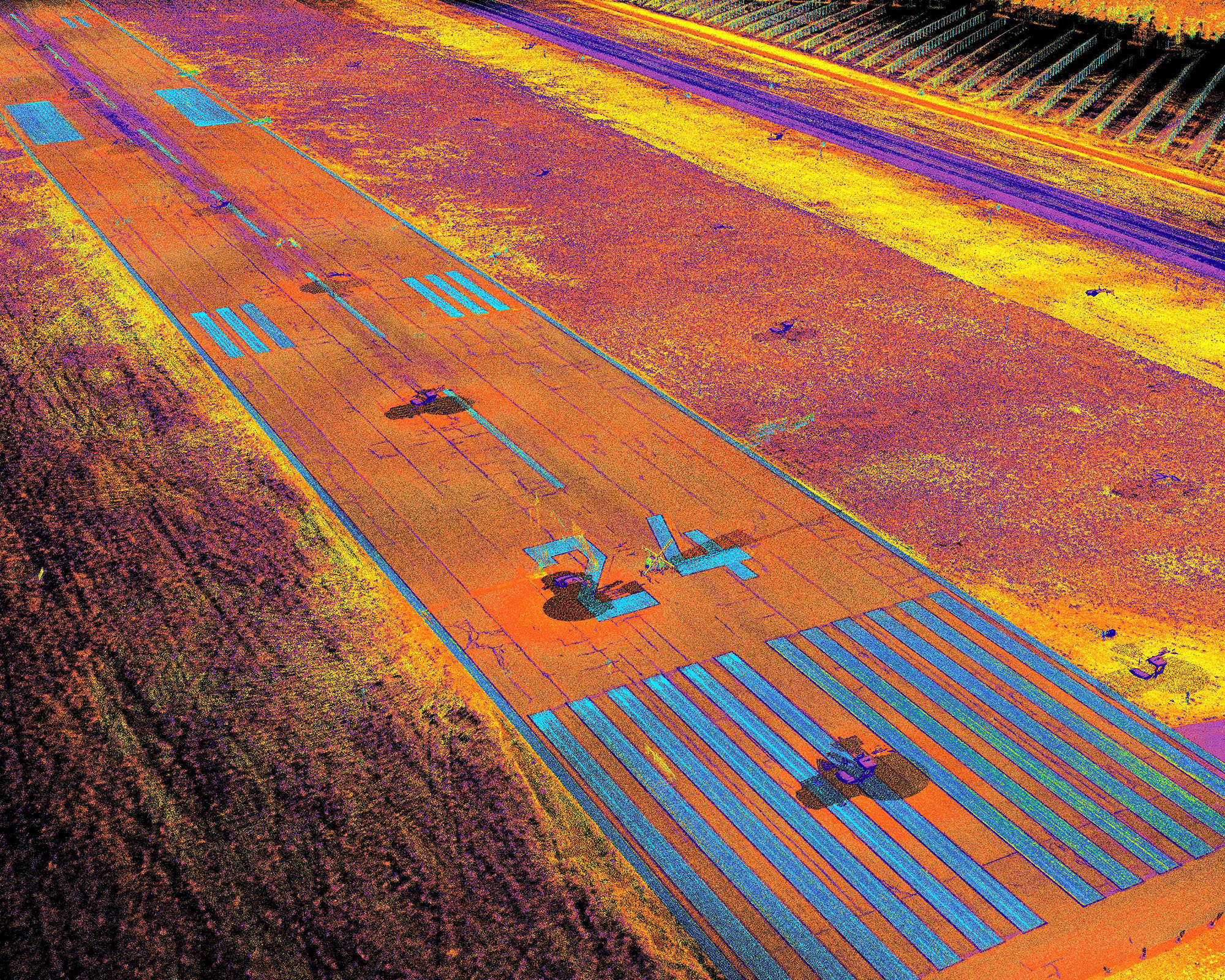

The client required a highly detailed topographic surface and asset location map of runway, taxi, and field areas at Barnstable Municipal Airport. ScanX3D executed an innovative solution to large scale data collection by using terrestrial laser scanning and truck mounted platform technology. This allowed for high speed, high fidelity laser measurements of the ground surface -fueling the development of a high quality digital terrain model and 2D plan drawing.

The vehicle was driven from scan position to scan position 150 times over the course of five business days. The laser scanning data was tied to airport coordinate control using 45 ground control points across the entire project. This ensured that all data was united seamlessly while maintaining real world coordinates. Data throughout the scope of work was assessed prior to extraction using surveyed validation points and rigorous QA/QC procedures.

Topographic information was extracted from the pointcloud using TopoDOT, an add on for Microstation. Technicians using the software, sampled elevation data every 25’ in earthen areas to create a perfect elevation grid used in surface creation. After delineating the paved area from the surrounding data, cross sections were created of the runway every 20’ by sampling along the centerline. The end product was a high quality surface and topographic plan used by the design team.